Introduction of replacement slurry pumps for International famous brands

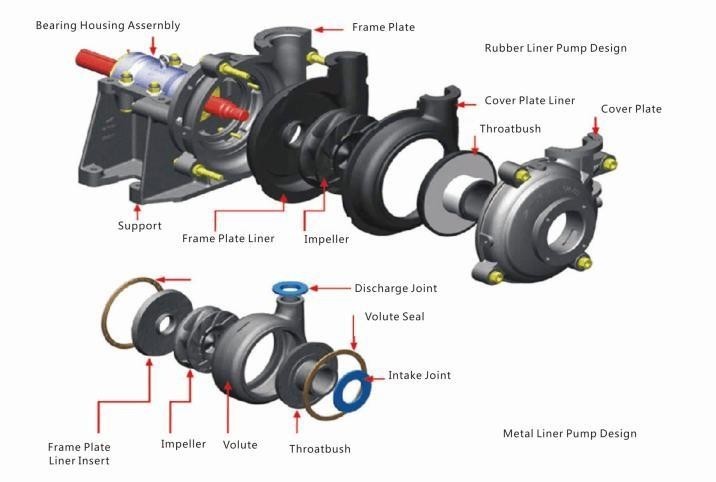

The replacement slurry pumps are cantilevered, horizontal and centrifugal slurry pumps. The wet end part can use wear resistance metal,rubber and ceremic. It can be used for metallurgy, mining, coal, electric power and building material to transmit slurry with strong corrosion and high concentration.

Features:

1.All the spares can be changeable with international slurry pumps. the wetted parts’ material can be optional as metal, rubber, or ceramic according to customer’s requirement

2.Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

3.Volute Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure moulded elastomer.

4. Elastomer seal rings back all liner joints.

5.Pump casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

6. Impeller–front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and moulded elastomer impellers are completely interchangeable.

7.CNC machining impeller threads require no inserts or nuts. High efficiency and high head designs are also available

8.Throat bush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

9.One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly.

10.An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

11. Pump exit position- Based on 45 degree interval, rotating eight different angles of installation.

Slurry Pump Bracket Type Description

| Bracket Type | A | B | C | D | E | R | F | G | S | T |

| Allowable Max Power(kw) | 7.5 | 15 | 30 | 60 | 120 | 300 | 260 | 600 | 560 | 1200 |

| Bracket Weight(kw) | 17 | 24 | 45 | 77.5 | 154 | 228 | 555 | 1006 | 546 | 1156 |

| Shaft Water Volume | 0.15 | 0.25 | 0.35 | 0.55 | 0.70 | 0.70 | 0.70 | 1.20 | 1.20 | 1.60 |

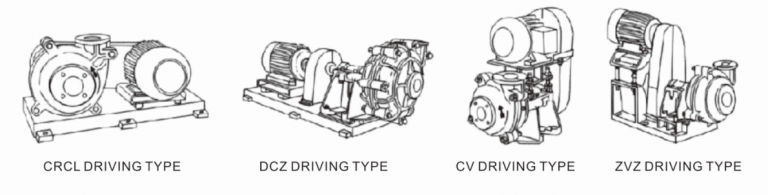

Slurry Pump Transmission Type

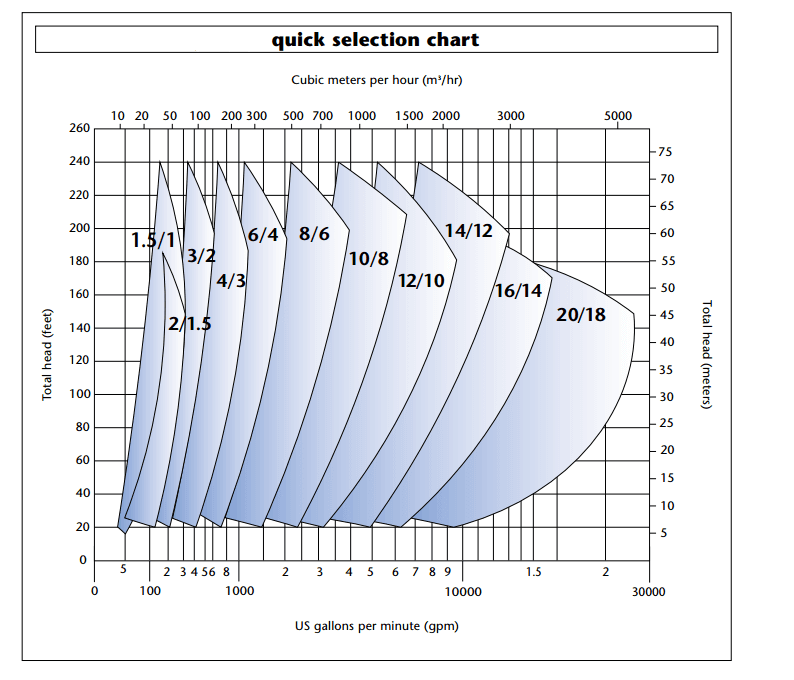

Slurry Pump Performance Chart